The Invisible Danger: Why "Slim" Power Tracks Often Sacrifice Your Safety

In the world of interior design, "slim" is often marketed as "superior." However, in electrical engineering, a thinner profile usually comes at a hidden cost: the omission of a full-sized earth connection. While many competitors reduce their tracks to the bare minimum—using thin "trick" strips or even omitting the ground entirely to save space—Line8 refuses to shrink the very component that keeps you safe.

In the world of interior design, "slim" and "minimalist" are often seen as superior. However, in electrical engineering, slimming down a power track often comes at a high price: the removal of the full-sized earth connection.

While competitors trim their profiles to look sleeker on your backsplash, Line8 refuses to compromise on the most critical component of electrical protection. Here is how to spot the difference yourself and why Line8’s "over-engineered" approach is the only one that truly protects your home.

The "Pin Test": How to Spot an Unsafe Adaptor

Singapore 3-Pin Plug featuring a full-sized earth contact

You can easily identify the quality of a power track by looking at the back of the adaptor (the side that enters the track).

Think of a standard Singapore 3-pin plug. You have three distinct pins: Live, Neutral, and the largest, longest pin at the top—the Earth. This Earth pin is oversized for a reason: it must be the first to connect and the last to disconnect, providing a massive "drainpipe" for stray electricity.

The Competitor Flaw: Most "slim" competitor adaptors feature only 2 connectivity pins on the key side. They omit the third physical pin to keep the track profile thin.

The "Trick" Strip: Some brands use a flimsy, thin metal strip to make contact with the track housing. This is often just enough to "trick" a basic socket tester into showing a green light, but it lacks the surface area to safely discharge a real electrical surge.

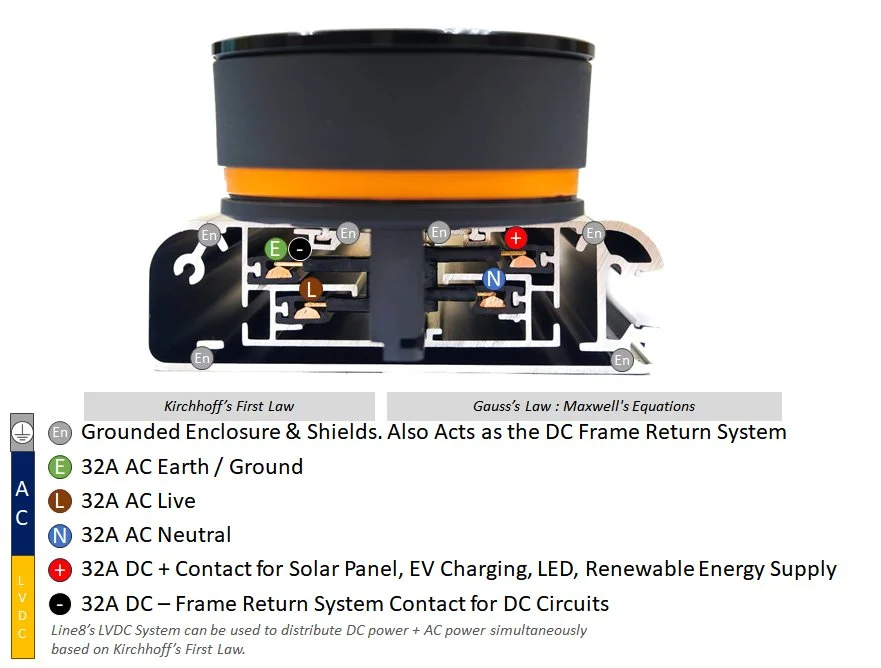

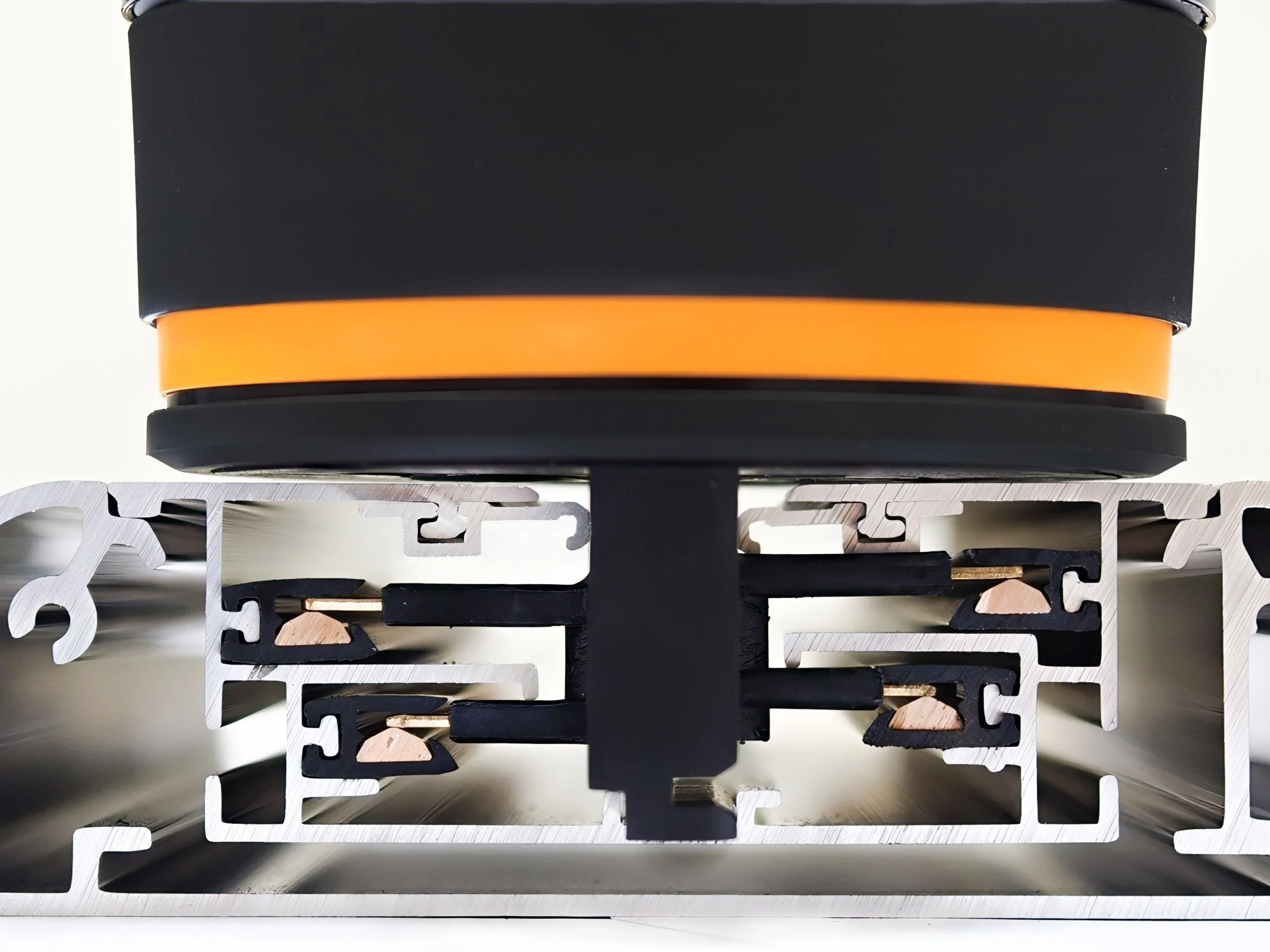

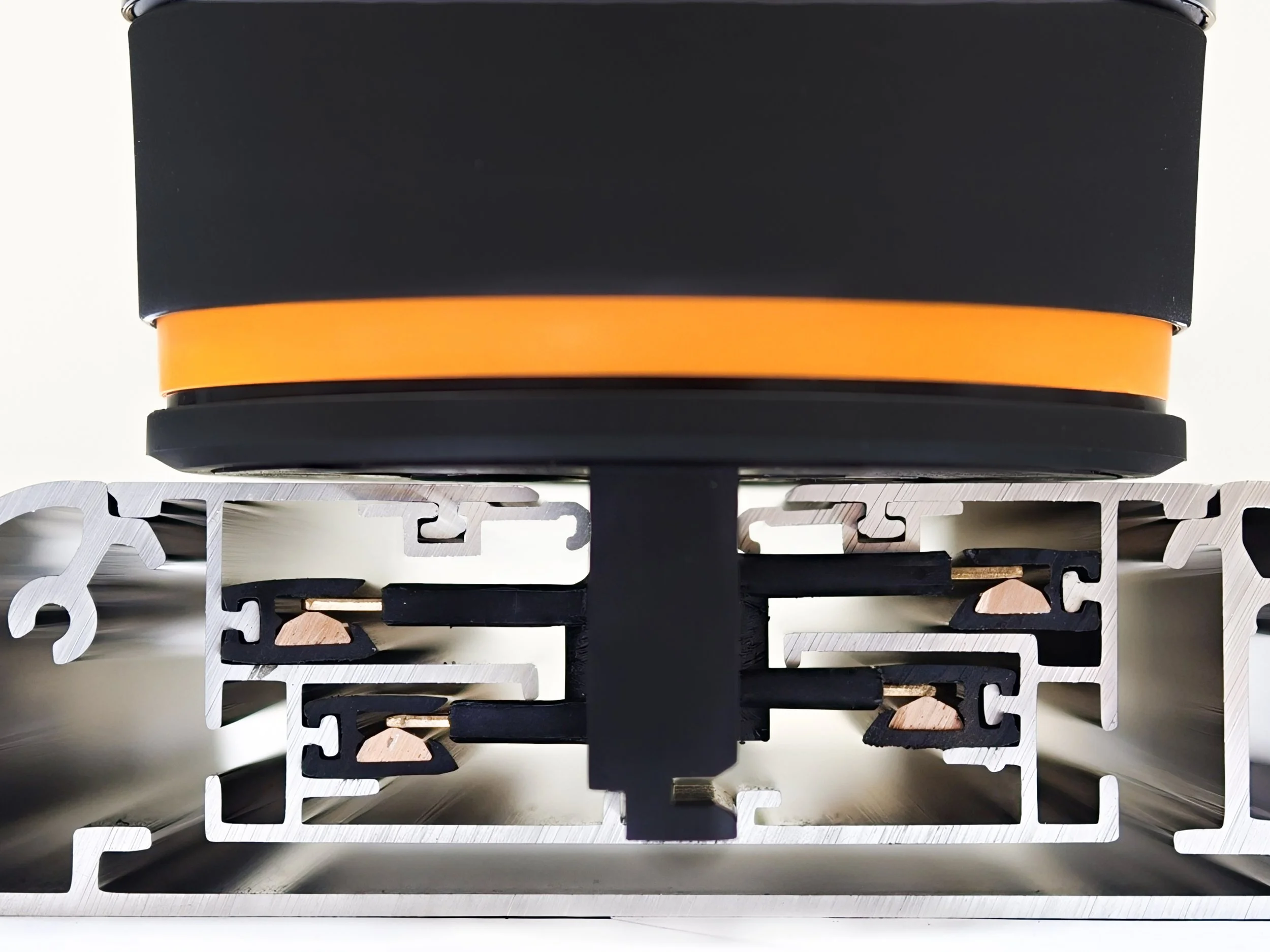

The Line8 Standard: Every Line8 adaptor features 4 robust pins. This ensures a high-capacity, physical connection for Live, Neutral, DC, and a full sized Earth system that exceeds the rated power of the track current capacity.

Line8’s System utilises a full-sized earth while other brand’s 2-pin design omits a full-sized earth contact to save cost and allowing the track to be slimmer.

Line8’s "Neural Network" of Grounding

While others try to omit or minimize the earth connection, Line8 treats it as a structural priority. We don't just use a single wire; we use an Active Grounded Shield architecture.

The Line8 system is designed from the ground up for the future. Featuring “tomorrow’s” green energy grid LVDC systems built into every track. Ready to be fired up anytime by including the DC + Conductor Bus-rail.

1. The Quad-Pin Connection

By using four pins instead of two, Line8 ensures that we have a dedicated Earth contact. Supplemented by the grounded enclosure & shields which ensures greater cross sectional area than the Live and Neutral lines. This allows for a massive current-carrying capacity, ensuring that if a fault occurs, the electricity is neutralized instantly.

2. The Aluminium Enclosure "Safety Net"

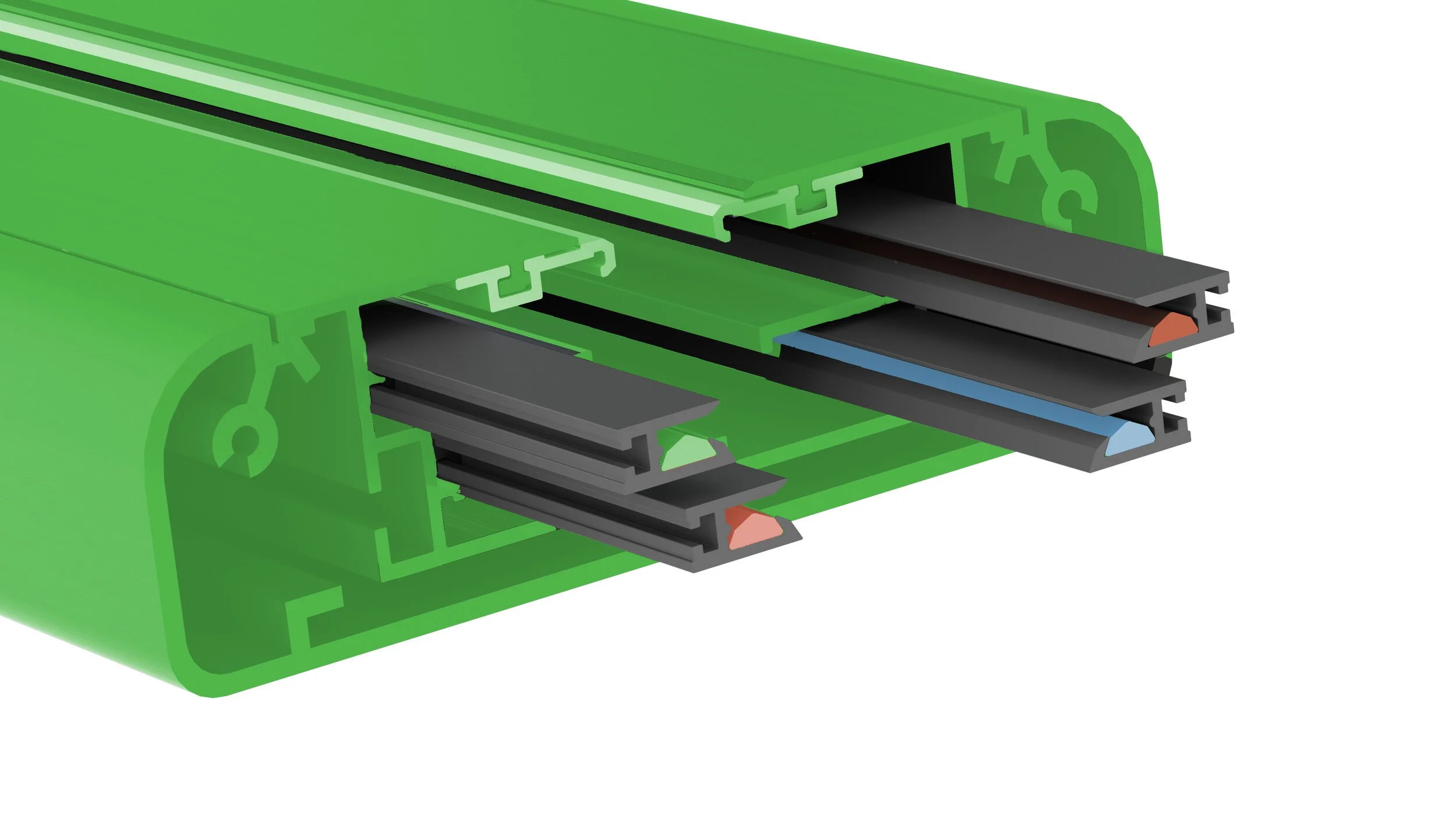

Line8’s aluminium enclosure and core is integrated into the earthing circuit

Unlike plastic tracks or aluminium shell tracks, the entire Line8 aluminium enclosure & core is integrated into the earthing circuit.

The opening of the track is flanked by our Patented Active Grounded Shield.

This creates a "neural network" of ground points surrounding the internal conductors.

If a stray wire or a foreign object (like a fork or a damp cloth or even water) touches the track, the grounded shield is positioned to "arrest" the leakage before it can reach the user.

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

The Silent Guard: Why Line8’s Full-Sized Earth Connection Sets a New Standard for Power Tracks

Most power tracks look great on the outside, but have you seen the engineering beneath the surface?

While some brands cut costs with thin, high-resistance earth conductors, Line8 uses a Full-Sized Earth Connection. Why does that matter? Read on to find out more.

When choosing a power track system, most users focus on the sleek aesthetics or the convenience of "plugging in anywhere." However, beneath the surface of these modern electrical solutions lies a critical engineering detail that many brands overlook: the earth connection.

While competitors often cut costs by using thinner, lower-grade earth conductors—or omitting them entirely—Line8 has engineered its system with a full-sized 32A earth connection. Here is an informative look at why this "silent" feature is the most important factor in your home's electrical safety.

1. The Engineering Gap: Full-Sized vs. Underpowered Earth

In a standard electrical circuit, the earth (ground) wire is your primary defense against electrocution. Its job is to provide a low-resistance path for "fault current" to escape safely to the ground if an appliance fails.

The Hidden Shortcut: Many power track systems use thin, higher-resistance strips for the earth connection to save on material costs (copper). In some cases, the earth conductor is omitted entirely, relying on the track's outer casing—which may not provide a continuous or reliable path.

The Line8 Advantage: Line8 uses a full-sized earth conductor that matches the current-carrying capacity of the Live and Neutral rails. This ensures that in the event of a massive surge or "earth leakage," the track can handle the full discharge without overheating or failing, triggering your home’s circuit breaker instantly as intended.

Why it matters: A lower-grade earth conductor can act like a "bottleneck" during a short circuit. If it cannot carry the fault current, the electricity may seek the next easiest path—which could be through the person touching the appliance.

Line8’s Power Track Core - Featuring a patented 4 terminal (Earth, Live, Neutral, DC) 32A 99.99% ETP Copper Conductors

2. Safety by Design: Beyond the Specification Sheet

Standard specifications often highlight current carrying capacity (e.g., 32A , 8000W), but they rarely detail the earth discharge capability.

| Feature | Line8 Power Tracks | Common Competitor Tracks |

|---|---|---|

| Earth Conductor | Full-Sized & Dedicated: Equal to Live/Neutral capacity. | Often reduced gauge or high-resistance strips. |

| Grounded Shielding | Active Grounded Shield: Dual strips protect internal contacts. | Often absent; exposed conductors pose a risk to children. |

| Engagement | Unidirectional: Prevents Live/Neutral reversal. | Some allow bidirectional use, risking incorrect wiring. |

| Materials | High-Performance Thermoplastics: Glass-fiber PBT. | Standard ABS or PVC (lower heat/fire resistance). |

3. Solving Durability and Safety Problems

Line8 doesn't just meet standards; it solves the inherent weaknesses of the "power track" concept through three key innovations:

A. Triple-Redundancy Safety

Line8 employs a patented "Lock-and-Key" system. The conductors are securely enclosed and remain in an "always off" state. Power only flows when a Line8 adaptor is fully inserted and rotated. This prevents accidental activation by "itchy hands" or foreign objects.

B. Space-Age Materials for Lifespan

While many brands use common plastics like ABS, Line8 utilizes Glass-Fiber Reinforced PBT and Xyron conductor carriers. These materials are:

V0-Fire Resistant: They will not support combustion.

Electrically Impermeable: Higher insulation strength than standard plastics.

Structurally Rigid: They do not warp under the heat of high electrical loads, ensuring the electrical connection remains tight for decades.

C. Eliminating Electrical Arcing

One of the biggest causes of wear in power tracks is "arcing"—the sparks that occur when you plug in an adaptor when under load. Line8’s adaptors feature a silver nickel mechanical switch that only completes the circuit after the mechanical connection is secure.

Line8 Power Track in Pearl White Finish with our range of power, lighting, IoT, SMART, Surge Protection, mmWave Sensing, IP Camera adpaptors.

4. Line8 Tracks: An Investment in Protection

A power track is a permanent installation in your home, often carrying the electrical load of an entire kitchen or entertainment center. While a competitor might look similar on the outside, the lack of a robust, full-sized earth connection is a hidden compromise in safety.

By choosing Line8, you aren't just buying a "fancy power strip"—you are installing a miniaturized industrial bus-bar system designed with the same safety margins found in high power electrical distribution design.

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

Can Power Track Adaptors Ever be Bi-Directional?

**Enhancing Electrical Safety with the Line8 Power Track System**

The Line8 Power Track System offers a flexible and safe solution for modern power needs, allowing users to easily add and move power sockets. Unlike some competitors' bidirectional adaptors, which can reverse live and neutral connections and pose serious safety risks, Line8’s unidirectional adaptors ensure correct and secure wiring. This commitment to safety is crucial, as incorrect wiring can lead to hazards, appliance damage, and non-compliance with electrical codes. When choosing power track systems, always verify that adaptors can only be inserted in one direction to ensure safe and proper operation.

Enhancing Electrical Safety with Line8 Power Track System

The modern home and workspace demand flexibility and convenience in their power solutions. The Line8 Power Track System stands out as a revolutionary product designed to meet these needs. With the ability to add and move power sockets along the track at will, users can enjoy a level of adaptability and safety previously unimaginable.

Line8: Redefining Modular Power Adaptors

At the heart of the Line8 system are its modular adaptors, which provide a safe and user-friendly way to engage power sockets. When a socket is connected to the Line8 track, it replicates the electrical connection of having a certified electrician install an additional wall socket.

An Example of Bi-directional Engagement Marketed as a “Feature”.

Addressing Concerns About Engagement Direction

There have been some concerns regarding the engagement direction of adaptors in power track systems. Competitors' products may allow bidirectional or upside down engagement of adaptors, seemingly offering more convenience. However, this feature can compromise safety.

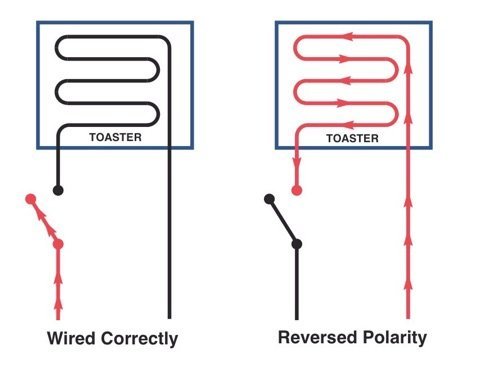

The Risks of Bidirectional Engagement

Engaging power adaptors bidirectionally poses significant risks due to the potential reversal of live and neutral connections. Here are the key hazards associated with this design flaw:

Safety Hazard: Reversing live and neutral connections can lead to internal wiring being energized even when switched off. Typically, a switch controls the live connection. When connected incorrectly, the switch would control the neutral instead, creating a dangerous situation where parts of the appliance or socket could remain live even when turned off.

Appliance Damage: Many appliances are sensitive to connection polarity. Incorrect wiring can cause appliances to malfunction or even sustain damage. Ensuring the correct connection is vital for the proper functioning and longevity of electrical devices.

Electrical Code Compliance: Electrical codes mandate correct wiring to ensure safety and proper operation. Non-compliance with these codes due to bidirectional engagement could lead to severe legal and safety repercussions.

Line8’s Commitment to Safety

The Line8 Power Track System addresses these concerns by allowing adaptor engagement in only one direction. This design choice guarantees that live and neutral connections are always correctly aligned, eliminating the risks associated with bidirectional engagement. By prioritizing user safety and appliance protection, Line8 demonstrates a thorough understanding of electrical safety principles.

Misleading Safety Certifications

It's important to note that while some products may carry safety certifications, these often only cover the socket on the adaptor, not the overall system's safety. In Singapore, for instance, the safety mark certification does not extend to ensuring the correct connection of adaptors to the power track. This oversight can give a false sense of security, highlighting the importance of a comprehensive approach to electrical safety.

Conclusion

The Line8 Power Track System sets a new standard for flexibility and safety in modular power solutions. By ensuring unidirectional engagement of adaptors, Line8 eliminates the dangers associated with reversed live and neutral connections. This commitment to safety, combined with the system’s ease of use, makes Line8 the superior choice for anyone looking to enhance their electrical setup. Prioritizing safety over misleading convenience features underscores Line8’s dedication to protecting users and their appliances.

Ensuring Your Safety

When considering power track systems, it's crucial to check that the adaptors can only be inserted in one direction. This ensures that the wiring is correct and safe. Always verify this feature before making a purchase to protect yourself and your appliances from potential hazards. By choosing systems like Line8, which prioritize correct engagement and safety, you can enjoy both convenience and peace of mind.

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

Knowing the Difference between White Label, OEM and In-House Manufactured Products.

In today's business world, companies have several options when it comes to developing and selling products. Three terms that are commonly used are white label products, OEM products, and in-house manufactured products. While they may seem similar, there are fundamental differences between these types of products. In this post, we'll explore the differences between white label products, OEM products, and in-house manufactured products.

Knowing the Difference between White Label, OEM and In-House Manufactured Products.

In today's business world, companies have several options when it comes to developing and selling products. Three terms that are commonly used are white label products, OEM products, and in-house manufactured products. While they may seem similar, there are fundamental differences between these types of products. In this post, we'll explore the differences between white label products, OEM products, and in-house manufactured products.

What are White Label Products?

White label products are products that are produced by one company and then rebranded by another company to sell as its own. The company that sells the white label product does not produce the product itself. Instead, it purchases the product from a manufacturer and puts its own label on it.

For example, a company that wants to sell a line of skincare products may purchase pre-made products from a manufacturer and rebrand them with its own label. This way, the company can sell the skincare products as its own product without having to invest in research and development or production costs.

White label products are often used by retailers who want to offer a product that they don't manufacture themselves. It's an easy way for them to enter new markets and expand their product offerings without having to invest in research and development or manufacturing capabilities.

However there are several trade-offs:

Limited control over the product: Since the product is produced by a third-party manufacturer, the company selling the white-label product has limited control over the product's quality, design, and features.

Dependency on the manufacturer: If the manufacturer experiences production or quality issues, it can impact the company's ability to sell the product. Additionally, if the manufacturer decides to stop producing the product, the company selling the white-label product may be left without a product to sell.

What are OEM Products?

OEM products, on the other hand, are products that are designed and manufactured by one company and then sold to another company to sell under its own brand name. The original company is known as the Original Equipment Manufacturer (OEM).

For example, a company that wants to sell a line of smartphones under its own brand name can work with an OEM to design and manufacture the smartphones to its specifications. The smartphones will then be sold under the company's brand name, but they will have been designed and manufactured by the OEM.

OEM products are often superior to white-label products as the products are specifically designed and often contain proprietary technologies and the company will have full control over the performance and design of the product.

What are In-House Manufactured Products?

In-house manufactured products are products that are designed and manufactured by the same company. The company has full control over the design, production, and branding of the product.

For example, a company that specializes in the production of power track will design and manufacture its own power tracks in-house. This allows the company to have complete control over the product's design, quality, and branding.

In-house manufacturing is often used by companies that have the expertise and resources to develop and manufacture their own products. It allows them to have complete control over the product and the ability to make changes and improvements quickly.

In-house manufactured products are known to be superior as there is full direct control from design, R&D and manufacturing of the product.

Conclusion

In summary, Line8 is proud to produce all our products in-house and hence you can rest assured that we have full control over the design, technology and how the products are manufactured. This allows us to imbue every Line8 product with cutting-edge technology. Because we manufacture everything in-house yon can be sure that our service and support or even additional plugs you might need in the future will be still available in years to come.

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

Why does Line8 Choose to Manufacture products in Singapore

SINGAPOREAN TECHNOLOGY

The main electrical distribution and safety technology of the power track system is developed right here and the patents are filed from right here in Singapore.

By manufacturing our tracks and products in Singapore, we keep the technology safe from copycats. They might reverse engineer and copy the design, but they will be missing the key safety technologies which are patent protected.

WHY DOES LINE8 CHOOSE TO MANUFACTURE PRODUCTS IN SINGAPORE

When almost every product is made in China. Why does Line8 choose to produce all their tracks and adaptors in Singapore?

SINGAPOREAN TECHNOLOGY

The main electrical distribution and safety technology of the power track system is developed right here and the patents are filed from right here in Singapore.

By manufacturing our tracks and products in Singapore, we keep the technology safe from copycats. They might reverse engineer and copy the design, but they will be missing the key safety technologies which are patent protected.

STATE OF THE ART PRODUCT DESIGN

With the expertise of Singaporean scientists and engineers from A*Star SIMTECH Singapore the product is designed from the ground up with manufacturing efficiency in mind.

With these key engineering features which are difficult to duplicate; we save as much as 90% of the labour required compared to other power track products.

This allows us to take full advantage of the high-tech, high-quality manufacturing standards of Singapore while remaining price competitive.

ACCESS TO SPACE AGE MATERIALS

Because of the extremely high labour cost in Singapore, only the best quality components and most high tech and high precision products are made here. This gives us access to space age materials like Fibre Glass Reinforced PBT.

These materials usually cost 5 to 10 times more than the common ABS plastics commonly used in products made in China. Furthermore they lack the technology to work with and produce products from these high-tech composite materials.

A SUPPORT LOCAL STATEMENT

At Line8 we believe in giving back and developing the capabilities of Singaporean Industry. To support local manufacturing and industry we have deliberately choose to manufacture all the components from the plugs to the screws we use in Singapore. We hope our Singaporean customer support local and in turn Line8 will also support local by procuring and producing our components right here in Singapore.

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

Common Misconceptions on Electrical Safety

Our modern electrical safety system is a system that has evolved throughout the last 100 years, since the proliferation of electrical supply in homes. Each safety mechanism is human-kind learning from our mistakes. They are put in place to address an accident that caused damage or took human lives.

Fast forward to today, most of us take it for granted and do not understand how these systems work. And this same lack of understanding shrouds product designers of electrical appliances (power tracks included) today.

Lest we forget, every time we use an electrical appliance there are risks involved.

ELECTRICAL SAFETY SYSTEMS

Our modern electrical safety system is a system that has evolved throughout the last 100 years, since the proliferation of electrical supply in homes. Each safety mechanism is human-kind learning from our mistakes. They are put in place to address an accident that caused damage or took human lives.

Fast forward to today, most of us take it for granted and do not understand how these systems work. And this same lack of understanding shrouds product designers of electrical appliances (power tracks included) today.

Lest we forget, every time we use an electrical appliance there are risks involved.

THE FORGOTTEN DB

Most of us have seen something like this somewhere in our home. But I bet most of us do not know that this is what stands between us and certain death.

So, we all have this box in our homes, are we all certainly safe? Yes and no. You see, for this to work, the electrical appliances need to be fully compatible. So it depends on the design of the device; if it is compatible or not.

THE SAFETY SYSTEMS

There are 3 major safety systems we are looking at in most electrical systems

ELCB – To save the human from electrocution when an appliance fails

The ELCB (Earth Leakage Circuit Breaker) works by detecting the presence of fault currents from live to the earth (ground) wire. For this to work the appliance should have a grounded enclosure to ensure that electrical leakage to the part of the appliance that we handle is detected before it causes harm.

RCD - To save the human from electrocution when he/she accidentally gets into contact with the Live or Neutral electrical paths

The RCD (Residual Current Device) is an ingenious device that ensures that the incoming and outgoing current is balanced. Signifying that no human or pet has absorbed (redirected) any energy from the electrical system. Once an imbalance is detected, it might imply that someone has been electrocuted, and the system will immediately be shut off to prevent the continuous electrocution of the person which might save his/her life.

MCB – To make sure that the wiring is not overloaded which will cause an electrical fire

The MCB (Miniature Circuit Breaker) is a protection device which ensures that only a specified amount of electrical current is carried by the electrical cables. Electrical cables are non-intelligent and will not “call for help” when there is too much current flowing through. Eventually, the cables will overheat and start an electrical fire. So the MCB is there as the “brains” of the electrical wire and will signal for a shut-off when the cable is overloaded.

POWER TRACK DESIGN

Power track systems are electrical distribution devices. It makes common sense that the design of the power track should be compatible with all the 3 above-mentioned safety systems right? Absolutely! However, did you know that more than 80% of power track brands are made in China and they are not compatible with one or more of the above safety systems?

To summarise, it is important that the power track system that you are considering is designed by a professional electrical engineer and not by a typical industrial or product designer. Designers are trained in art. Engineers are trained in physics and math.

Choose wisely, Line8 is the only product in the market designed fully by a professional electrical engineer.

https://wireworkscoinc.com/2016/07/when-was-electricity-widely-used/

https://www.nps.gov/edis/learn/kidsyouth/the-electric-light-system-phonograph-motion-pictures.htm#:~:text=In%201882%20Edison%20helped%20form,the%20U.S.%20have%20electric%20power.

https://en.wikipedia.org/wiki/Earth-leakage_circuit_breaker

https://www.electrical4u.com/working-principle-of-earth-leakage-circuit-breaker-elcb-voltage-current-elcb-rccb/

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

What is a Power Track and why do we need one?

The power track is the solution to the problem. There are certain areas like the kitchen, TV console and the study area that are difficult to perfectly predict the number of sockets and where to place them. For areas like these, we can cater for a power track to be installed during renovation. This track will be the infrastructure where we can then add as many sockets as we need anywhere along the track.

A Common Problem

Power tracks are a relatively new product category. Prior to its invention, we are accustomed to fit conventional power sockets around the home and office during renovation. Guessing how many sockets will be required and where to place them are a few difficult decisions we need to make.

The Makeshift Method

No matter how hard we try to predict there will always be not enough sockets and there will always be the socket that is at the wrong location. To solve this, we will then look towards purchasing one of these extension strips or these multi-plugs. They do help in easing the situation, but it is not a true solution. To add, these apparatuses are typically not as safe and also do not last as long and there are risks of overload if one connects too many appliances via these makeshift solutions.

The Power Track Solution

The power track is the solution to the problem. There are certain areas like the kitchen, TV console and the study area that are difficult to perfectly predict the number of sockets and where to place them. For areas like these, we can cater for a power track to be installed during renovation. This track will be the infrastructure where we can then add as many sockets as we need anywhere along the track.

Solving The Overloading Issue

The Line8 Power Track System utilises a patented tap-off connection that is the industry standard in electrical power distribution. Using the tap-off method that is synonymous with how a licensed electrician installs additional sockets to a home or office, the Line8 Power Track and adaptor connection prevent the overloading issue that plagues extension strips and multiplugs.

How to choose a power track

Now we all know that power tracks add a level of modularity and flexibility to our homes and offices. What makes a good power track and what are the factors we need to consider?

Reputable Brand

A reputable brand will ensure that the necessary components like switches and electrical conductors are made of quality materials. Necessary safety components like grounding and switches are not omitted.

Certification and Testing

Electrical safety is important and electrical products are one of the most regulated products. In Singapore it is mandatory that power track adaptors need to be tested to Singapore Standard certification and attain SAFETY MARK. On top of that, there are numerous other standards like British Standard, ISO and IEC.

Future support and availability

Installing a power track in your home or office means that additional sockets can be added in the future. However choosing a reputable brand will ensure that you can still purchase additional adaptors when you need them, many years to come.

Durability, Design and Materials

Power Tracks are precision-made devices that are pushing the boundary of modern material science. A properly designed power track is made to replace the big distribution box that we typically have in our homes and offices with something sleek and modern while having the same electrical capabilities. There might be other products that look like Line8 Power Tracks, but are actually just power extensions or multiplugs made to look like a power track and hence they don’t have the proper capability.

Warranty

Having a longer warranty covered by a reputable local company will ensure that you will have peace of mind while enjoying the benefits of the product and you will be able to get service when you need it.

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

The Inspiration Behind Line8 Power Tracks (Part 2)

Line8 uses the exact same type of connection the electrician or professional Electrical Engineer would have used to distribute power. only that we have converted the complicated wiring diagram into a simple twist mechanism.

So by adding a Line8 adaptor into the track. It's the same technically correct wiring method as how a professional electrician would have added a power socket on your wall manually.

The power track concept takes its inspiration from the simple and common track light. The track light is a common fitting seen in many retail shops and even homes. With a simple track installed on the ceiling, we can now add, reposition and remove lighting points as and when we like. This is exceptionally useful when it’s difficult to plan the number of spotlights you need and where you need them during the renovation phase as the placement of subjects that need lighting.

The power track is a very similar invention in solving a very similar problem. The difference that we’re talking about electrical sockets here instead of spotlights. The features that separate these two products will be their safety and electrical load capability. Last week I touched on the safety aspect of the design and this week I will share more about the innovations behind the electrical load capability.

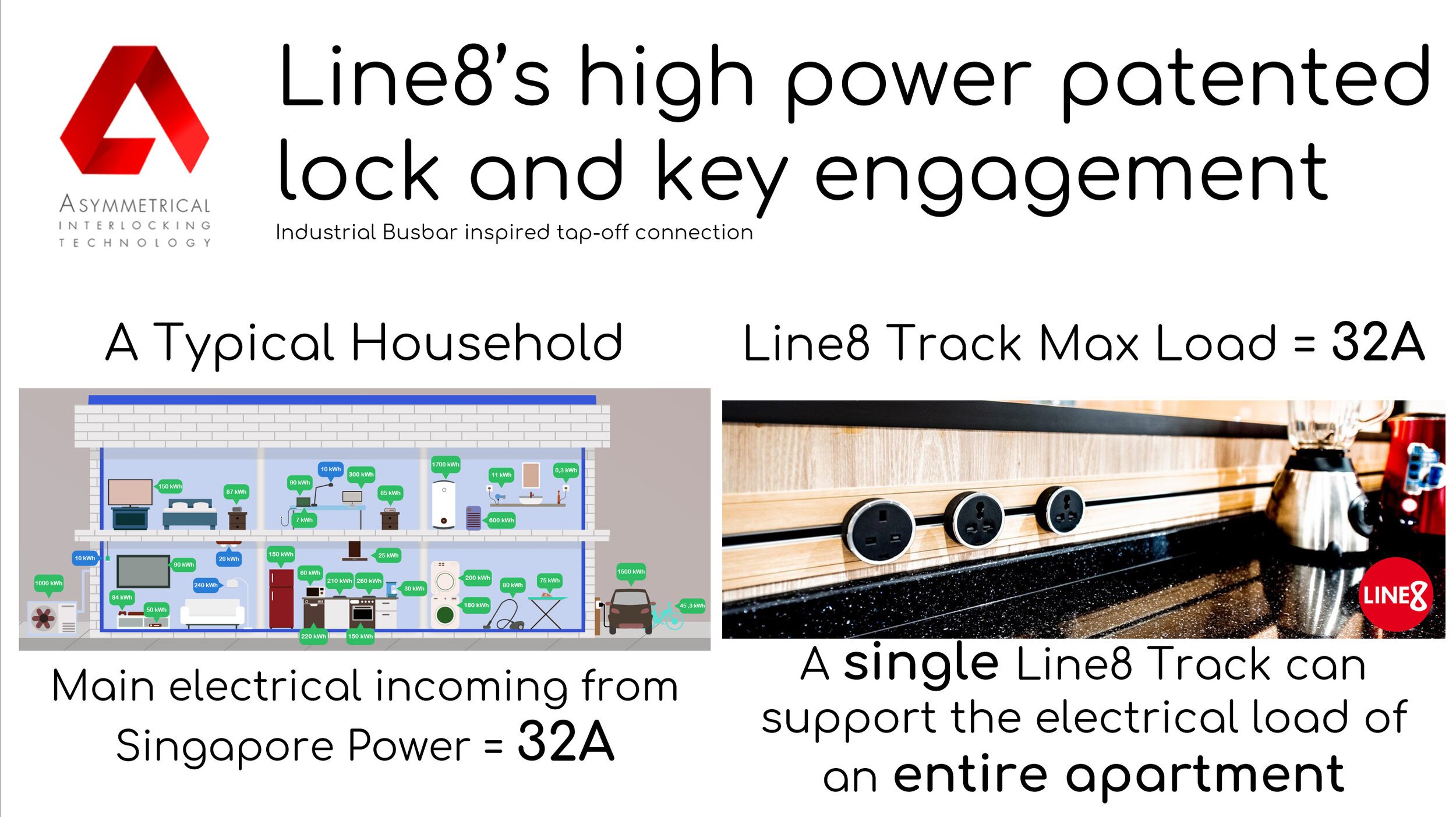

Power Loading Capability

The electrical power track is designed for users to be able to add, remove, and reposition power sockets freely and safely. The Line8 Power Track will be able to accommodate no less than 14 sockets per meter of track.

To be able to support a large number of sockets, a different kind of electrical connection must be used. This kind of connection is not as revolutionary as it is commonly used to distribute power throughout a building using an electrical bus bar as the power distribution device. The Line8 power track simply a miniature bus bar that has been designed and adapted for use in our interior space rather than in the electrical riser of a building.

All homes typically have a single big incoming electrical wire from Singapore Power that the electrician will then use to distribute it all around the home.

The method of connection the electrician will use to distribute the power throughout the house is called a tap-off circuit connection. This kind of connection is different from the ones typically found in the normal multi-plug or extension plug. That is why there will be an overload risk if multi or extension plugs is used. However, we are usually not as concerned about how many electrical points we are getting the electrician to add to your whole house.

For example, a 2 room flat and a 5 room executive maisonette has the same 40A electrical main cable from Singapore Power. But the 5 room will logically have a lot more plugs than a 2 room. But there is no overloading risk in the 5 room.

The Significance

The key to making that possible is the tap off electrical connection. It is also the same way our government distributes power to every household in a HDB block.

This is how a typical electrical bus bar look like

Line8 uses the exact same type of connection the electrician or professional Electrical Engineer would have used to distribute power. only that we have converted the complicated wiring diagram into a simple twist mechanism.

So by adding a Line8 adaptor into the track. It's the same technically correct wiring method as how a professional electrician would have added a power socket on your wall manually.

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

The Inspiration Behind Line8 Power Tracks

The power track concept takes its inspiration from the simple and common track light. The track light is a common fitting seen in many retail shops and even homes. With a simple track installed on the ceiling, we can now add, reposition and remove lighting points as and when we like. This is exceptionally useful when it’s difficult to plan the number of spotlights you need and where you need them during the renovation phase as the placement of subjects that need lighting.

The power track is a very similar invention in solving a very similar problem. The difference that we’re talking about electrical sockets here instead of spotlights. The features that separate these two products will be their safety and electrical load capability. This week I will touch on the safety aspect of the design and I will share more about the innovations behind the electrical load capability next week.

Numerous people have asked me; what’s the inspiration behind the Line8 Power Track and what makes it stand out among other power tracks and the conventional power socket?

The power track concept takes its inspiration from the simple and common track light. The track light is a common fitting seen in many retail shops and even homes. With a simple track installed on the ceiling, we can now add, reposition and remove lighting points as and when we like. This is exceptionally useful when it’s difficult to plan the number of spotlights you need and where you need them during the renovation phase as the placement of subjects that need lighting.

The power track is a very similar invention in solving a very similar problem. The difference that we’re talking about electrical sockets here instead of spotlights. The features that separate these two products will be their safety and electrical load capability. This week I will touch on the safety aspect of the design and I will share more about the innovations behind the electrical load capability next week.

Safety

It is not easy to put a finger inside a track light as it is typically mounted on the ceiling; away from children and itchy hands. The power track different. It is typically mounted where it is accessible. Accessible for us to plug in, switch on and off and also to children and itchy hands.

To add, the electrical socket market is a lot more regulated with very specific safety standards and safety requirements since it has to safeguard against accidents, electrocutions, and misuse.

Line8 made the leap by inventing the TRS safety technology which is made possible by two actively grounded conductor strips flanking the openings of the power track that grounds everything that comes into contact with the opening of the power track.

Grounded means that if there's any leakage of electricity, it will be neutralized to ground instead of passing through the body of the person. This acts as an electrical shield for the person. It is The Faraday’s Cage Theory. Just that instead of putting the person in a cage, the power track is put in a grounded cage instead.

The two shiny metal strips on the opening of the Line8 track not only highlight and accentuate the design. It is also there to act as the Faraday’s Cage inspired electrical shield. This grounded shield will cage up all the components inside the power track which then shields the outside from any electrical leakage.

The Significance

The electrical shield in a power track is a fundamental technology. It is a required feature before any power track is placed within access to its users, children, and itchy hands. In fact, all competing power track brands (except Eubiq with their GSS invention) are not designed by electrical engineers. Without understanding the importance of this, they have omitted this critical feature from their products. Whatever safety feature they have claimed, having a grounded shield is the most basic and none of them seem to have featured such a technology in their design.

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

The reason why power tracks need to be expensive & why would you want to pay more for your power track

The reason why power tracks need to be expensive & why would you want to pay more for your power track.

With the surge of popularity of the power track concept, it has caught the attention of numerous Chinese manufacturers. Similar to many other products, these new Chinese brands feel that they are able to produce something similar for cheaper. However, power tracks are not the common fast-moving consumer goods (FMCG). Power tracks are a highly engineered product that pushes the boundary of modern material sciences.

The reason why power tracks need to be expensive & why would you want to pay more for your power track.

With the surge of popularity of the power track concept, it has caught the attention of numerous Chinese manufacturers. Similar to many other products, these new Chinese brands feel that they are able to produce something similar for cheaper. However, power tracks are not the common fast-moving consumer goods (FMCG). Power tracks are a highly engineered product that pushes the boundary of modern material sciences.

Imagine, a single Line8 Power Track can carry the amount of power as an entire HDB or Condo apartment. Yes, everything in the apartment from the air-conditioning, all appliances, and lights in all kitchen, sitting area, and rooms…plug all that into one single Line8 Power Track and you haven’t overloaded the Line8 Power Track yet.

As much as it sounds impossible, it is made possible by the extensive use of High-performance thermoplastics (HPTPs). The Line8 Adaptor is made from a glass-fiber reinforced polybutylene terephthalate. This gives the Line8 Adaptor characteristics like V0-fire resistance, chemical resistance, high electrical strength, and high rigidity. The Line8 Power Track Conductor Assembly is made from a Super-Engineering Thermoplastic called Xyron (mPPE based) just to name a couple.

High-performance thermoplastics (HPTPs) - What are they and why are they important

Pyramid of Thermoplastics

High-performance thermoplastics (HPTPs) are thermo-polymers that meet higher requirements than standard or engineering thermoplastics. They are high-priced, low-volume polymers that are sold for use in specialized applications that require a combination of extraordinary properties (the most important being that of high-heat temperature tolerance and performance).

The main applications for HPTPs are electrical/electronics, automotive, aircraft/aerospace, industrial (including oil and energy), and health (medical/dental)

Why are HPTPs important in Power Track Manufacturing

Power Tracks are high-precision, high load power distribution devices. They will need to withstand a much higher electrical load and provide much more electrical power compared to a standard wall socket or any regular electrical appliance.

This kind of design load is typically fulfilled by large and bulky bas-bar systems that distribute power around any building and city.

Having to miniaturize this same technical design into something aesthetically pleasing and sleek requires the use of special materials. Materials than can insulate much better, materials that can withstand much more load, materials that can provide the mechanical and electrical properties

Many have thought, why didn’t power tracks become popular much earlier? The answer to the question is because we didn’t have these HPTPs available for use back then.

Commonly used materials like Polycarbonate (PC), ABS (Acrylonitrile Butadiene Styrene), and Polyvinyl Chloride (PVC) are just not good enough for the demanding electrical and mechanical required to produce a power track.

Not all power tracks are made equal

In conclusion, not all power tracks are made equal. Being made in Singapore and with our access to high-tech manufacturing through our collaboration with A*Star SIMTECH. Topped off with the extensive use of HPTPs. Every Line8 Power Track is proudly made in Singapore with the best in manufacturing technology and material science. A power track is not something that we can replace easily like a poorly made electrical kettle for example. It is something that is permanently installed in your home, therefore it is important to fit one that is known to last.

https://en.wikipedia.org/wiki/High-performance_plastics#cite_note-Elias4-1

https://ihsmarkit.com/products/chemical-high-performance-thermoplastics-scup.html

https://www.a-star.edu.sg/simtech/industry/industry-collaborations

https://services2.hdb.gov.sg/webapp/BN31AWERRCMobile/BN31SElectrical?loadAction=electrical

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg

How safe are power sockets and tracks?

The conventional power socket has come a long way.

Plugs and sockets for portable appliances became available in the 1880s, to replace connections to light sockets with wall-mounted outlets.

Today there are about 20 types in common use around the world. They are mainly developed for both convenience and protection from electrical injury.

THE CONVENTIONAL POWER SOCKET HAS COME A LONG WAY

Plugs and sockets for portable appliances became available in the 1880s, to replace connections to light sockets with wall-mounted outlets.

Today there are about 20 types in common use around the world. They are mainly developed for both convenience and protection from electrical injury.

https://en.wikipedia.org/wiki/AC_power_plugs_and_sockets

The conventional electrical socket is the outcome of countless innovations backed with safety modifications learned from previous accidents.

Trying to reinvent the power socket means that we need to consider all the safety and technical features that are built into every electrical socket to ensure the safety of its users.

REINVENTING THE POWER SOCKETS WITH POWER TRACKS

A power track is a power socket replacement. It aims to replace the conventional power socket to add the much-desired flexibility and technology to this 140-year-old invention.

As power tracks only came into popularity in the last couple of years, the regulatory and safety bodies are still trying to catch up and set a safety standard for these new hybrid devices.

SO HOW SAFE ARE POWER TRACKS?

Safety is of the utmost importance as there is a real life-threatening risk when one gets electrocuted from a poorly design or manufactured electrical power track.

There is essentially no risk when the power track is designed and manufactured by a reputable engineering and electrical firm that is well versed with electrical safety and its designs.

A POWER TRACK IS NOT A CONSUMER ELECTRICAL DEVICE

Power tracks are currently viewed by many as regular consumer electronics and manufacturing firms of regular consumer electronics are coming in with their designs that don’t adhere to the strict safety and engineering standards of a reputable electrical engineering firm.

It is soon that the safety and certification bodies will catch up with unsafe products. However, there is a window of opportunity for these consumer electronic manufacturing firms to come in and make a quick buck with their designs which fail to adhere to the strict safety guidelines that reputable electrical manufacturing firms adhere to.

Things from the wrong use of conductor materials, use of low voltage components for high voltage application, use of cheaper materials like copper and brass instead of the more expensive silver and gold where the use of these materials are required, poorly design or non-existent earth conductors and grounded shields, just to name a few. Conventional power sockets seldom have these shortcomings because proper certification is required before it can be sold.

CHOOSING THE CORRECT POWER TRACK

A good power track needs to have the following

An adequate gauge of the electrical conductor to carry the rated current

Proper grounding for enclosures and housing

Earth contact has to be first to make a connection and last to disconnect and the resistance and contact quality and gauge needs to be equal to or more than the rated current

Well-engineered electrical path with as few as possible interconnects

Adequate cooling on all electrical conductors to prevent overheating in the event of overload

Overload protection to ensure that the load is less than the rated current of the power track

Durability and high MTBF for all mechanical and electrical components

Mechanisms which prevent or eliminate electrical arcing which will damage electrical contacts and raise resistance

Proper electrical switch design for the designed electrical load using precious metals to ensure a low resistance, corrosion-proof properties of the electrical switch.

Mechanisms to ensure the correct orientation and contact order of the electrical connection

Use of proper materials for insulators that have high electrical strength with good insulation properties with fire-resistance, heat resistance, and low wear properties.

Product Safety Tips for Consumers

http://www.scivee.tv/10-ways-to-protect-your-children-from-electrical-hazards/

https://www.ema.gov.sg/Electrical_Safety.aspx

Line8, a locally founded R&D and Engineering Company develops and manufactures the Line8 Power Track System. Our products have proven to be innovative and aesthetically pleasing in many of our customer's homes locally and overseas.

Learn more at : www.line8.com.sg